Supercapacitors power wireless sensors

Today’s sensors are often wireless, powered by a small battery or an energy harvester which may not be able to provide the peak power necessary for data transmission. CAP-XX supercapacitors can be charged at low power and supply the peak power needed.

Supercapacitors deliver peak power for data transmission.

Most wireless sensors are designed to be long lasting, autonomously powered set and forget units. They are typically powered by a small primary battery or for a maintenance free solution, a small energy harvester. Extremely energy efficient electronics coupled with a low power, low data rate wide area wireless technology is essential but even low data rate, “low power” protocols such as LoRa, NB-IoT, and LTE CAT-M1 which enable reporting over a campus area or wide area require power levels in the range of 0.5W – 1.5W. Even short range reporting using BLE requires a peak of power of 10mW. These power levels are beyond most micro energy harvesters, such as a small solar solar cell, or piezo-electric transducer that typically provide < 1mW. The can charge a supercapacitor at very low power and the supercapacitor provides the peak power when data is transmitted. Most batteries can support BLE transmission, but the longer range protocols that require ≥ 0.5W are beyond the capability of most coin cells which have a typical internal impedance of 5Ω – 10Ω. A CAP-XX supercapacitor with an Equivalent Series Resistance of ~100mΩ will easily supply the peak power. CAP-XX supercapacitors have very low leakage current, ~1µA/F , so precious power from a harvester or energy from a battery is not wasted. CAP-XX also offer a range of thin prismatic supercapacitors, ideal for sleek and unobtrusive sensors.

APPLICATON BRIEF

AB1007 Rev 1.4

Supercapacitors in wireless sensors

Today’s sensors are often wireless, powered by a battery or an energy harvester for a maintenance free solution. Often due to size or other constrains, such as harvestable power, the preferred energy source cannot provide the power needs of the system, particularly for data transmission. CAP-XX supercapacitors can be charged at very low power from an energy harvester or battery to supply the peak power for wireless data transmission.

Supercapacitor working with a battery

Most standalone wireless sensors are designed to be long lasting, set and forget units. Extremely energy efficient electronics coupled with a low power, low data rate wide area wireless technology is essential. The data quantity and update rate is are often low, in the 100’s of Kb/s making protocols such as LoRa, NB-IoT, and LTE CAT-M1 suitable for these applications.

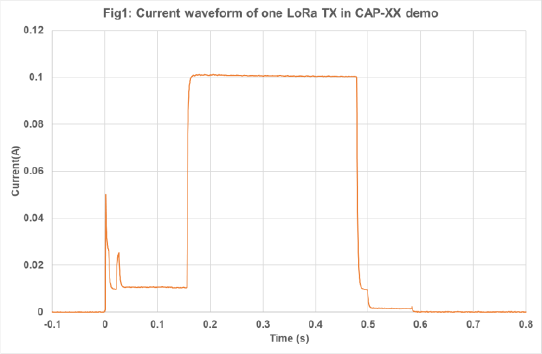

Fig 1 is the current waveform of a single data packet transmission using a CAP-XX LoRa wireless sensor evaluation board (see photo). The current peaks at 100mA for ~0.35s. This 0.5s waveform includes the electronics initialising, taking a light sensor reading and finally transmitting the data via LoRa radio. The evaluation board consumes 0.09J of energy per transmission and its standby current is around 0.5µA.

A primary battery such as a C size 7.7Ah LS26500 LiSOCl2 contains over 27Wh of energy. It can support the CAP-XX wireless sensor demo for over 1 million transmissions ignoring standby current draw and other losses.

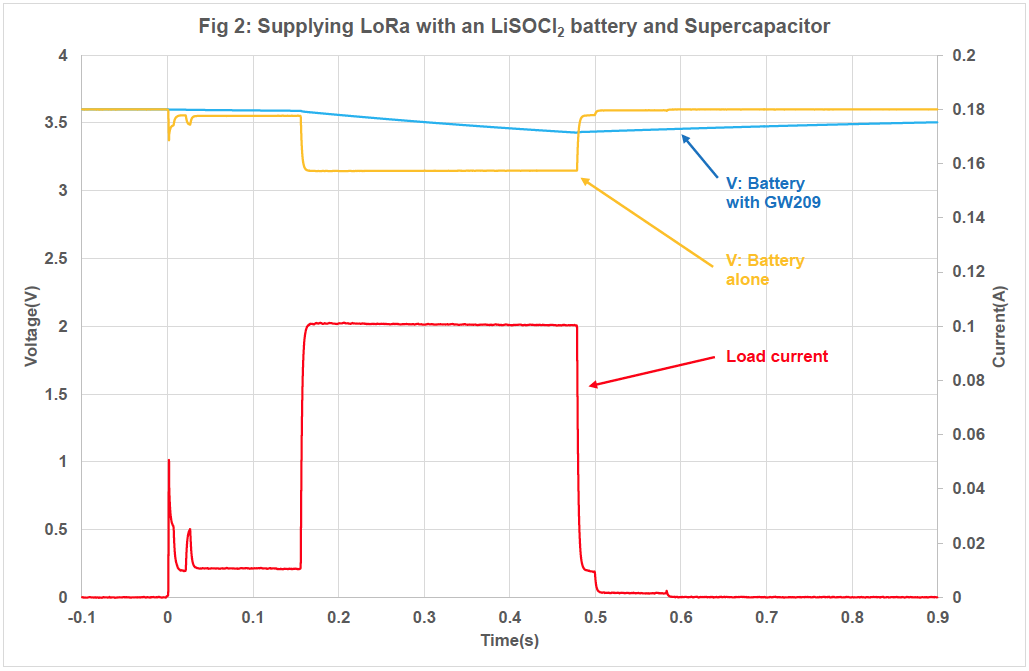

However, high energy Lithium Thionyl Chloride batteries such as the Saft LS26500 have high internal impedance. This causes a significant voltage droop, even when supplying peak currents that are only 100mA. Fig 2 shows the battery supporting the LoRa Tx pulse with and without a CAP-XX GW209 supercapacitor, 160mF, 55mΩ.

Without the supercapacitor the battery voltage drops ~0.45V to ~3.15V due to the high battery internal resistance = ~4.5Ω. For some modules, this voltage drop may cause a brown out from the first pulse. With the support of a GW209 supercapacitor the voltage drop at the end of the pulse is only 0.19V to 3.41V. This is due to supercapacitor discharge. With a higher C supercapacitor, such as a GS230, 1.2F, the voltage would only drop ~30mV.

A CAP-XX supercapacitor is an ideal power buffer to help greatly increase the battery life without sacrificing any features. Using a GW201 in parallel with the battery shares the current inversely proportional to their impedance, so the only battery provides 0.055/(0.055+4.5) = 1.2% of the current. As the supercapacitor discharges the battery provides charge current limited by its internal resistance, = (3.6V – 3.41V)/4.5Ω = 42mA.

For more information please refer to Coupling a Supercapacitor with a Battery.

Supercapacitor stores energy from a harvester

Another maintenance free alternative is to use an energy harvester, which theoretically allows the device to run indefinitely. Unfortunately, energy harvesters such as small solar cells, RF harvesters and vibration transducers produce very low power, typically in the sub mW range.

A supercapacitor can be charged at low power from the energy harvester. The supercap’s low ESR ensures minimum voltage drop during transmission peaks and the high capacitance provides the energy storage for one or more transmissions, and can keep operating the sensor for some time after the environmental energy has gone (e.g. no light).

Examples of supercaps with energy harvester are:

Solar cells to power sensors (Charging a Supercapacitor from a Solar Cell Energy Harvester) reporting data wirelessly.

Vibration transducers (micro-generator or piezo electric) to power sensors (Charging a Supercapacitor with Vibration energy harvester)

Sizing your supercapacitor

CAP-XX supercapacitors can deliver high power due to their low ESR, have high C to supply sufficient energy to support the data capture and transmission for its duration, have “unlimited” cycle life, and can be charged at very low current, see our latest range of DMF low ESR high power, DMT long life high temp or DMH ultra thin supercapacitors. They are the perfect power buffer between an energy harvester and sensor, see Powering Pulse Loads.

A range of ICs are available to charge supercapacitors from energy harvesters. To select the best IC consider the characteristics of your energy harvesting transducer, the minimum voltage the IC requires to start, if the IC has peak power tracking and the method it uses, min and max power levels and efficiency at those levels, and if it incorporates cell balancing for a dual cell supercapacitor, see Cell Balancing.

Inrush Current Limiting

Due to its low ESR, a CAP-XX supercapacitor will try to draw very high inrush current when initially charging from 0V. An energy harvester can usually supply short circuit current and in most cases a battery’s internal impedance will act as a sufficient current limit, but if inrush current limiting is required to protect the battery, then see Current Limiting for Supercapacitors.